What Is Die Banking?

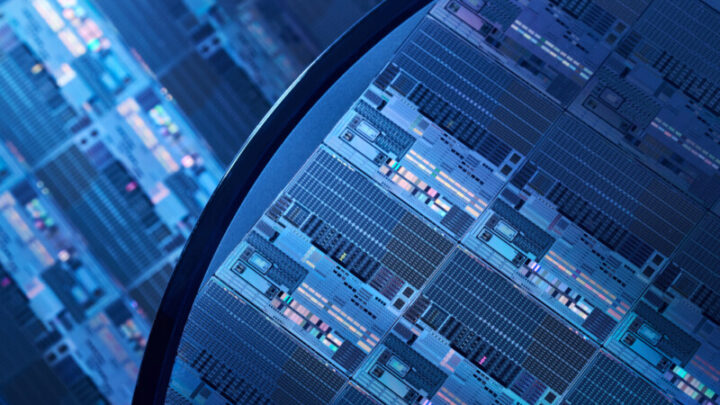

Die banking is a process through which raw die and wafer is stored by a manufacturer until it is required for ASIC assembly. Because of its ability to keep manufacturers from continuously re-entering the marketplace, die banking is a great way to help avoid price increases, extended lead times, and many kinds of supply chain…